Carbon Footprint Improvement

What’s on your mind

How do I calculate the greenhouse gas emissions for my products, processes or company? What actions can I take to reduce my carbon footprint so my company becomes carbon neutral?

Optimize Your Carbon Footprint Improvement Strategies

As global temperatures inch closer to the 1.5°C warming threshold, the impacts of climate change continue to worsen for communities worldwide. Now, consumer awareness surrounding carbon footprints has increased and governmental institutions have enacted regulations to reduce greenhouse gas (GHG) emissions in everything from transportation and the energy sector to agriculture and imported goods. Reducing the carbon footprint of your company or product has a range of benefits alongside legal compliance and increased consumer trust: it can actively contribute to reducing climate change and its effects, improving public health, stimulating economic growth and helping protect our planet’s biodiversity.

Meo Carbon Solutions specializes in empowering customers to reduce the carbon footprints of entire companies and their products—including transportation, renewable resources, fossil- and bio-based wastes and residues, renewable energies, biofuels, agriculture and chemical industries. Through short-term consultancies, our dedicated team provides GHG calculators based on ISO standards and the GHG Protocol and life cycle assessment (LCA) for all levels of a supply chain, for products, processes or an entire corporation. These calculators are successfully implemented in certification audits under the Renewable Energy Directive (REDII), Fuel Quality Directive (FQD) and other standards such as the ISO. The team also offers longer-term projects to help develop GHG certification systems, conduct pilot audits and more.

Work Case

Climate Friendly Coffee & Carbon Footprint Reduction

Approach

MCS conducts the project in 4 steps:

- Definition of system boundaries & sample group

- Data collection and analysis

- Development of GHG calculator

- Provision of results and discussion of improvement measures

Overview

A coffee producer in Asia cultivates robusta coffee on its plantations and would like to get its supply chain emissions calculated to be able to define its carbon footprint and implement mitigation measures to reduce the emissions generated by its coffee production process. As a voluntary market the coffee sector is not regulated by defined governmental laws with regard to emissions thresholds, but more and more producers and companies dealing with coffee want to get active and do set individual voluntary goals and reduction targets for their business and products.

The coffee producer has asked Meo Carbon Solutions to do the initial GHG emissions calculation for its company from cradle-to-gate, meaning from the cultivation of the coffee cherry to the processed and dried green coffee bean ready for distribution.

Step 1: Definition of system boundaries & sample group

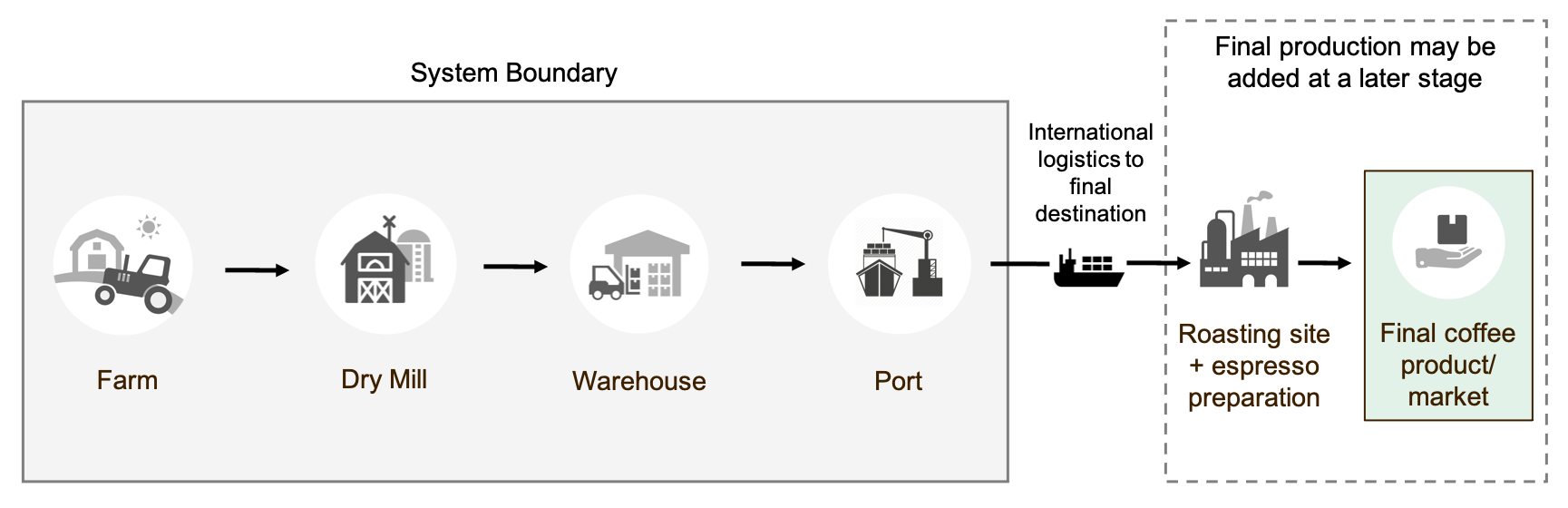

The basic step for each GHG emissions calculation is the definition of system boundaries for the respective supply chain and production pathway to determine which inputs and resulting emissions need to be included in the calculation. For the GHG emissions calculation of a coffee supply chain MCS considers all steps from cultivation to port of export including transportation and all interim processes like washing, drying, packing until the green coffee beans are ready to be exported. The final production stage at the roaster in the target country can be added on a voluntary base. The GHG calculation is based on a defined sample which represents the whole farm group in hectare & size, location, distance to mill, cultivation practices, yield and certification status. The results for this sample can be later used as basis to be upscaled to whole farm group level.

Please see below a figure of a typical system boundary for this work case.

Step 2: Data collection and analysis

Based on the defined system boundaries of the supply chain and the group of sample farms, resulting necessary information and data by the coffee producer is collected via individualized data templates for each step of the supply chain. The process of data collection is flexible and can be conducted in different ways e.g. via paper-based templates per farmer up to a mobile app if necessary digital conditions are available. Once received, MCS checks the data on completeness and detects potential missing data necessary to do the GHG calculation. Such data gabs are filled by intensive communication and feedback loops with the company and the farmers.

Step 3: Development of GHG calculator

MCS uses the collected company information and process data to develop the individual GHG calculator for the whole coffee supply chain including all production steps from cradle-to-gate which means cultivation, process and transport emissions.

Step 4: Provision of results and discussion of improvement measures

At the end of the project MCS provides to the coffee producer an open, transparent and audit-ready GHG calculator including results and emission values for each supply chain step and the final green coffee. The calculator in its form can be used to apply for a certification under a sustainability certification scheme requiring a GHG calculation in the audit. In addition, MCS consults the coffee producer in selecting the optimum improvement measures to effectively reduce emissions and thereof improve the carbon footprint of the final green coffee.